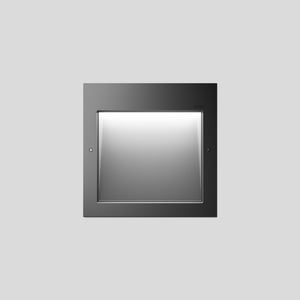

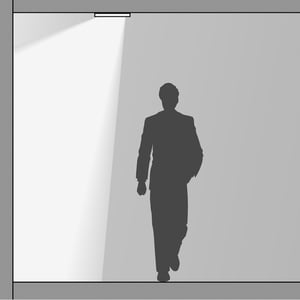

For decades, BEGA luminaires from this series have been outstanding lighting construction details on numerous structures worldwide. We are constantly developing these luminaires and always perfectly match the construction and design to our LED technology. The extremely low maintenance requirements allow a new product concept with far easier and quicker installation. The electrical connection is comfortably established before installation in the structure. The installed luminaire is then mounted securely in the structure or in the installation housing with our BEGA mounting system. All installation dimensions are identical to those of the previous luminaires. The slim yet screwless luminaire frames are highly distinctive.

The unshielded luminaires and the luminaires with asymmetrical flat beam light distribution are available in a version as combined LED emergency luminaires with integrated single battery for 3 hours of emergency operation in case of mains failure (according to EN 60598-2-22).

Technical data

The unshielded luminaires are optionally available as luminaires for applications requiring a higher degree of illuminance or as location luminaires with lower light output.

Protection class IP 65 BEGA Thermal Management®

Cast aluminium, aluminium and stainless steel BEGA Unidure® coating technology Safety glass

20-year availability guarantee for replacement parts and LED modules